The W.H. Howell Foundry was formed in 1860 as a manufacturer of cast iron products such as flat irons, fluters, and piano benches. In 1923, Howell Company moved production to turning out metal furniture partly because electricity came along, making the old fashioned flat iron obsolete. During World War II, Howell Company began manufacturing stainless steel mess trays for the U.S. Navy, along with artillery shells, sections of airplane wings and fuselages, and casings for 200 pound fragmentation bombs.

Photo courtesy St. Charles History Museum

Join us at the St. Charles History Museum as we explore how St. Charles industries contributed to America's war effort during World War II with our temporary exhibition Industry opening Saturday, March 26.

In the wake of Pearl Harbor, President Franklin D. Roosevelt set staggering goals for America's industries. War production during the 1940s profoundly changed American industry. Companies expanded, employment increased, the scarce effects of the Great Depression ended; thus the American economy would enter into a new dawn of economic prosperity.

The goals set by FDR were very much relevant in St. Charles, and many local businesses become involved with manufacturing goods for the War. We will feature artifacts from companies like Howell Company, Howard Aircraft Corporation, as well as Operadio all of which supported the war effort by converting their assembly lines to manufacture armaments and war material.

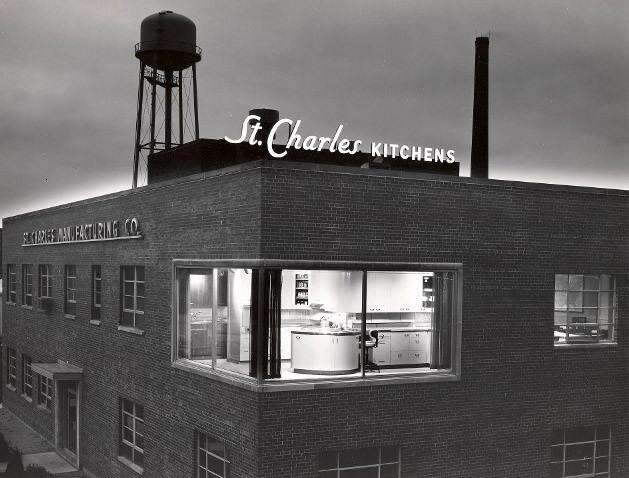

St. Charles Kitchen: Organized in 1935, the St. Charles Manufacturing Company began operations in custom kitchen design. The company's steel furniture became a trademarked brand.

Howell Company: The W.H. Howell Foundry was formed in 1860 as a manufacturer of cast iron products such as flat irons, fluters, and piano benches.

Operadio Manufacturing Company: Credited for building the first portable wireless radio in 1909, J. McWilliams Stone pioneered the way for electronics and founded Operadio.

Hawley Products Company: Partnering with the McCord Radiator and Manufacturing Company of Detroit and the Quartermaster Corps., Hawley Products Company manufactured the original M1 liner for helmets.

For details about this new exhibit, visit stcmuseum.org or call (630) 584-6967.

Got an idea for a suburban #TBT Gallery? Share your ideas and photos with us at tbt@dailyherald.com. Share your favorite and memorable #TBT photos with us on Instagram using #tbtsuburbs.

The W.H. Howell Foundry worker bending metal tubing, circa 1939. During World War II, Howell began manufacturing stainless steel mess trays for the U.S. Navy, along with artillery shells, sections of airplane wings and fuselages, and casings for 200 pound fragmentation bombs.

Photo courtesy St. Charles History Museum

Hawley Products Co.: Partnering with the McCord Radiator and Manufacturing Company of Detroit and the Quartermaster Corps, Hawley Products Company manufactured the original M1 liner for helmets. Hawley produced a total of 3,977,000 helmet liners from 1941 until it ceased production in 1942. From World War II to the Gulf War, Hawley Products Company also commissioned military sun helmets (pressed fiber pith helmets) for the war effort with the International Hat Company. The pressed fiber pith helmet is noted for its historic length of its combat use in the United States, outlasting the M1 steel helmet by roughly ten years.

Photo courtesy St. Charles History Museum

Assembly line for pith helmets.

Photo courtesy St. Charles History Museum

Photo courtesy St. Charles History MuseumFemale works stretching fabric for pith helmets at Hawley Products Co. in St. Charles.

Production at Hawley Manufacturing Company. Partnering with the McCord Radiator and Manufacturing Company of Detroit and the Quartermaster Corps, Hawley Products Company manufactured the original M1 liner for helmets. Hawley produced a total of 3,977,000 helmet liners from 1941 until it ceased production in 1942. From World War II to the Gulf War, Hawley Products Company also commissioned military sun helmets (pressed fiber pith helmets) for the war effort with the International Hat Company. The pressed fiber pith helmet is noted for its historic length of its combat use in the United States, outlasting the M1 steel helmet by roughly ten years.

Photo courtesy St. Charles History Museum

Hollywood film actor Sterling Hayden wears a pith helmet. Hayden joined the U.S. Marine Corps in 1943 as a private, under the name John Hamilton.

Photo courtesy St. Charles History Museum

A solder wears a pith helmet during a rescue mission.

Photo courtesy St. Charles History Museum

Ben Howard in front of DGA-6. Howard Aircraft Corporation was a small USA aircraft manufacturer in the 1930s and 1940s founded by Ben "Benny" Howard. The factory was initially on the south side of Chicago Municipal Airport at 5301 W. 65th Street and during World War II a second plant was opened at DuPage Airport. The onset of World War II signaled the end of the civil Howard aircraft liners and they began to produce commercial and military aircrafts that were noted for their outstanding ruggedness, performance and ease with which they are flown. The plane was nicknamed 'Mister Mulligan'.

Photo courtesy St. Charles History Museum

Howard DGAs practicing aerial formations. Howard Aircraft Corporation was a small USA aircraft manufacturer in the 1930s and 1940s founded by Ben "Benny" Howard. The factory was initially on the south side of Chicago Municipal Airport at 5301 W. 65th Street and during World War II a second plant was opened at DuPage Airport. The onset of World War II signaled the end of the civil Howard aircraft liners and they began to produce commercial and military aircrafts that were noted for their outstanding ruggedness, performance and ease with which they are flown. The plane was nicknamed 'Mister Mulligan'.

Photo courtesy St. Charles History Museum

Pallets being loaded on U.S. Army aircraft.

Photo courtesy St. Charles History Museum

Operadio: Operadio's first big sound system installation was at the 1930 National Air Races in Glenview. The sound system enabled 100,000 people to follow the events. Relocating from Chicago to St. Charles, Illinois, Operadio signed a lease with Lester J. Norris, who was responsible for bringing Operadio to St. Charles. With approach of World War II, European countries sought Operadio's skills. As orders piled in for a variety of military and naval equipment- ranging from tank intercoms to radar power units- war work at Operadio took over completely after Pearl Harbor.

Photo courtesy St. Charles History Museum

Operadio voice department. Operadio: Operadio's first big sound system installation was at the 1930 National Air Races in Glenview. Relocating from Chicago to St. Charles, Illinois, Operadio signed a lease with Lester J. Norris, who was responsible for bringing Operadio to St. Charles. With approach of World War II, European countries sought Operadio's skills. As orders piled in for a variety of military and naval equipment- ranging from tank intercoms to radar power units- war work at Operadio took over completely after Pearl Harbor.

Photo courtesy St. Charles History Museum

St. Charles Kitchens: Organized in 1935, the St. Charles Manufacturing Company began operations in custom kitchen design. The company's steel furniture became a trademarked brand. Within three years of producing "St. Charles Kitchens", the St. Charles Manufacturing Company interrupted its domestic production and converted all work toward the war effort. Steel was at a premium during World War II; St. Charles Kitchens assembly lines turned out millions of rounds of steel products, ammunition parts and parts for anti-aircraft weapons.

Photo courtesy St. Charles History Museum

St. Charles Manufacturing Company warehouse. Organized in 1935, the St. Charles Manufacturing Company began operations in custom kitchen design. The company's steel furniture became a trademarked brand. Within three years of producing "St. Charles Kitchens", the St. Charles Manufacturing Company interrupted its domestic production and converted all work toward the war effort. Steel was at a premium during World War II, St. Charles Kitchens assembly lines turned out millions of rounds of steel products, ammunition parts and parts for anti-aircraft weapons.

Photo courtesy St. Charles History Museum